Roman Concrete: The Enduring Legacy of an Ancient Technology

Updated on: 11 November 2025Reading time: 4 minutes

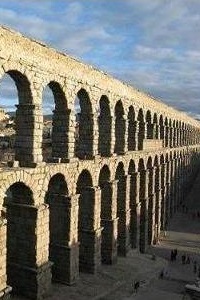

Roman concrete, called opus caementicium in Latin, was used from the late Roman Republic until the end of the Roman Empire. It was employed to build monuments, large buildings, and infrastructure such as roads and bridges. The quality of the concrete was excellent, and the buildings and monuments still standing today are a testament to the strength of their construction!

Concrete was usually covered, as bare concrete walls were considered unaesthetic. Roman builders covered building walls with stones or small square tuff blocks that would often form beautiful patterns, noting that brick-faced concrete buildings were common in Rome, especially after the Great Fire of 64 AD.

Roman concrete formula

Roman concrete, or opus caementicium, was invented in the late 3rd century BC when builders added a volcanic dust called pozzolana to mortar made of a mixture of lime or gypsum, brick or rock pieces, and water.

CC-BY-2.0 |

Concrete was made by mixing with water:

- an aggregate, which included pieces of rock, ceramic tile, or brick from previously demolished constructions,

- volcanic dust (called pozzolana), and

- gypsum or lime.

There were many variations of concrete, and Rome even experienced the so-called “Concrete Revolution”, which represented advances in the composition of concrete and allowed for the construction of impressive monuments such as the Pantheon. For example, Roman builders discovered that adding crushed terracotta to the mortar created a waterproof material which could then be used for cisterns and other constructions exposed to rain or water.

The Romans mastered underwater concrete by the middle of the 1st century AD. The city of Caesarea provides an impressive example of Roman construction. The production technique was quite incredible: the mix was one part lime to two parts volcanic ash, and it was placed in volcanic tuff or small wooden cases. The seawater would then hydrate the lime and trigger a hot chemical reaction that hardened the concrete.

Caesarea harbor before and today - Robert Teringo, National Geographic Society |

Was Roman concrete better than modern concrete?

It has actually been argued that the concrete used by the Romans was of better quality than the concrete in use today. Recent research by US and Italian scientists has shown that the concrete used to make Roman harbours in the Mediterranean was more resistant than modern concrete (known as Portland cement).

The production process was dramatically different. Portland cement is made by heating clays and limestone at high temperatures (various additives are also included), whereas the Romans used volcanic ash and a much smaller amount of lime, heated at lower temperatures than modern methods.

For example, Roman harbours remain intact today after 2,000 years of waves breaking on their breakwaters, whereas Portland concrete begins to erode in less than 50 years of sea battering. The concrete from ancient Rome also possessed flexible properties that Portland concrete does not have, due to its lime and volcanic ash — which explains why it does not crack after a few decades.

Incredible facts about Roman concrete

|